How much cotton content is better for stretch denim fabric?

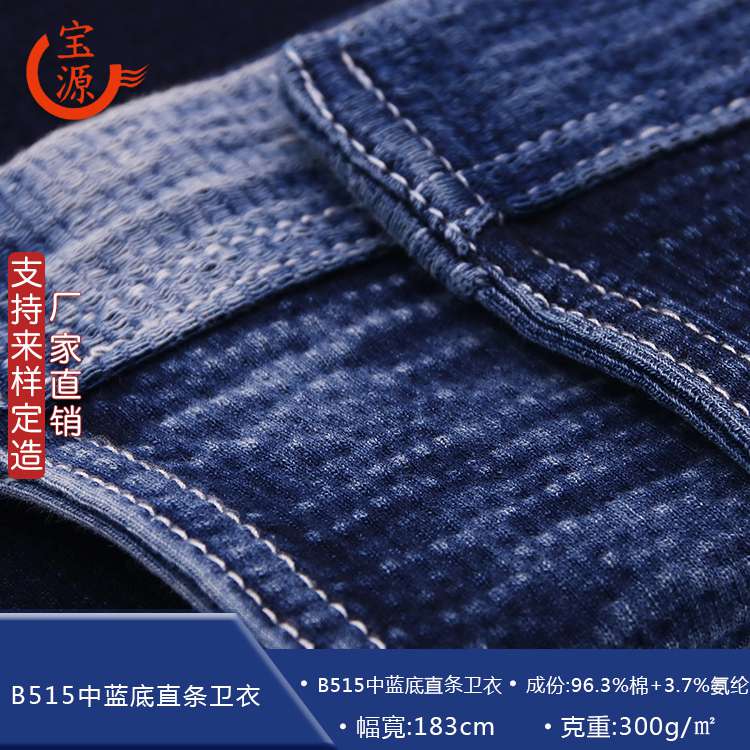

Denim fabric 100% cotton is the best, and more than 95% cotton content is suitable, which can make the fabric soft and comfortable, and excellent breathability.

Jeans are also known as "sturdy denim pants". A tight-fitting slacks for men and women. The front trousers are free of pleats, the back trousers are free of darts, the door is equipped with zippers, the front trousers are equipped with a diagonal bag on the left and right sides, the back trousers are equipped with two patch pockets with pointed waist, and the seam of the pocket opening is nailed with metal rivets and pressed with open lines for decoration. It is wearable, dirt-resistant, and comfortable to wear. Generally, it is made of indigo blue abrasive fabrics such as labor cloth, cow tendon labor cloth, and other fabrics such as suede, corduroy, velveteen, which are collectively referred to as "jeans".

Real jeans are made of 100% cotton denim, and even their stitches are made of cotton; Polyester blended fabric can also be used instead of cotton. The most commonly used dye is synthetic indigo. Traditional rivets are made of copper, but zippers and buttons are made of iron. Designers' signs are made of cloth, leather or plastic, and some are also embroidered on jeans with cotton thread.

From the perspective of denim fabric types, it can be divided into plain, twill, herringbone, crisscross, slub, dark, and flocked denim.

In terms of composition, denim is divided into combed and combed, including 100% cotton, elastic (Lycra), cotton and hemp blended, and Tencel.

In addition to the traditional products mentioned above, there are also pattern denim:

Pattern denim with different raw material structure;

(1) Elastic denim is woven by using a small proportion of spandex yarn (about 3-4% of the yarn weight) as the core elastic warp or weft of the warp yarn;

(2) Snow denim with white effect after dyeing, which is blended with low weight polyester and cotton as warp yarn;

(3) High grade denim made of cotton, hemp and cotton wool blended yarn;

(4) Denim woven with medium length fiber (T/R);

Pattern denim woven by different processing technologies

(1) Bark crepe denim woven with high twist weft yarn;

(2) In the process of warp dyeing, the dyed denim is dyed with indigo blue after being primed with vulcanized or Haichang blue dyes;

(3) Colored denim with colorful warp yarns embedded in indigo warp yarns;

(4) Hang white or print on indigo denim;

The article is from the manufacturer of elastic jeans:http://www.hsbyfz.com/

-

10-15

Knitted denim factory: weaving process of knitted denim

Weaving technology of knitted jeansThe application of knitted jeans in life can be said to be many, and the advantages of knitted jeans are also many, so it has been widely used in the clothing indust

-

07-08

The knitting denim factory introduces the washing methods and types

1. General washing means general washing. It's just to change the washing we know about everyday to mechanization. The water temperature is about 60 ° - 90 ° C, and a certain amount of detergent

-

04-08

Characteristics of coated denim

Coated denim refers to a kind of post-processing product of denim, which is evenly coated with macromolecular compounds that can form a film on the surface of denim to change the appearance, style or

-

03-04

The reason why elastic jeans have elasticity

Now we all love beauty and attach importance to the maintenance of body shape. Many people will choose some elastic clothes to highlight the curve when they have attractive body shape. Elastic jeans h